Silcotech North America: A Silicone Molding Success Story

Silcotech North America: A Silicone Molding Success Story

Over 25 years, Silcotech North America, based in Bolton, Ontario, has evolved from a small startup with two employees and two molding machines into a global leader in liquid silicone rubber (LSR) molding. Founded in 1998 by Michael Maloney and Isolde Boettger, the company now operates a state-of-the-art facility in Bolton and a production site in India, employing over 100 people.

Key Developments and Milestones

- Growth and Expansion: Silcotech went independent in 2010, expanding its Bolton facility and adding advanced injection molding equipment to support increasing demand.

- Notable Achievements: The company contributed to the success of innovative products like the Diva Cup and Trudell Medical’s respiratory care devices. It also developed a groundbreaking multi-color, multi-durometer LSR iPhone cover, showcasing its advanced molding capabilities.

- Industry Expertise: Silcotech excels in medical, healthcare, automotive, and consumer electronics sectors, leveraging LSR’s unique properties like heat stability and chemical resistance.

Innovation and Automation

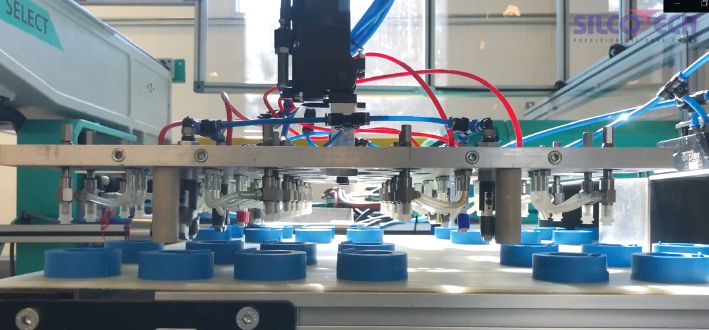

Silcotech designs and partially builds its own specialized tooling for LSR molding. The company integrates automation into its processes, enabling in-line assembly and reducing costs through efficient multi-shot molding. This approach minimizes inventory and supply chain complexity.

Commitment to Employees and Diversity

The company fosters employee development and emphasizes advancing women within its ranks, supported by Boettger’s background in education. This approach has resulted in low turnover and an inclusive workplace culture.

Challenges and Resilience

During the COVID-19 pandemic, Silcotech demonstrated industry leadership by sharing excess materials with competitors. It continues to outperform large plastic molders entering the LSR market, benefiting from its deep expertise and streamlined operations.

Future Plans

Silcotech aims to double its business in five years through continued growth, improved efficiency, and expanded automation. The company remains committed to pushing boundaries in LSR molding and maintaining its competitive edge.

To read the complete article click here.

LSR parts in production at Silcotech.